Friday, March 28

10E2344: If You Have Time To Lean...

Outside of 10engines starting a new work chapter next week - sort of corporate librarianship... a position with the digital asset management software company Image Relay. Have been looking at this for a while - very excited. I know some readers here are in the field (or parallels like knowledge manager etc) - look forward to further shop talk. Cheers.

Tuesday, March 25

10E2343: CB Sports - more

*text repeated from 2011

*still mining these things from ebay

At one time based near us in southern Vermont, CB Vaughan's line of sportswear was simply called CB Sports. Mentioned them forever ago and still like mining the late 70s-early 80s style on these ebay finds. Cut to the waist with chevron stitching and often using corduroy... these worked even better on women. They also did plenty of pullover windshirts/windbreakers too in simple red/blue combos.

After this initial period they jumped in hard on the 80s yellow/purple/lime surf inspired styles. Not all terrible, just prefer the blues/reds. Then they opened their own stores selling CB and other brands. By about 2006 they were no longer manufacturing their own items but there still existed CB Sports stores that sold general skiwear, those folded in 2008-ish.

Article from People magazine in 1982;

*still mining these things from ebay

At one time based near us in southern Vermont, CB Vaughan's line of sportswear was simply called CB Sports. Mentioned them forever ago and still like mining the late 70s-early 80s style on these ebay finds. Cut to the waist with chevron stitching and often using corduroy... these worked even better on women. They also did plenty of pullover windshirts/windbreakers too in simple red/blue combos.

After this initial period they jumped in hard on the 80s yellow/purple/lime surf inspired styles. Not all terrible, just prefer the blues/reds. Then they opened their own stores selling CB and other brands. By about 2006 they were no longer manufacturing their own items but there still existed CB Sports stores that sold general skiwear, those folded in 2008-ish.

Article from People magazine in 1982;

In spite of the recession that has frosted this year's market, the 40-year-old Vermonter [CB Vaughan] expects his Bennington-based company to gross $12 million. His CB logo has become the lift-line equivalent of the Lacoste alligator...

C.B. has taken some spills on the way to the top... Vaughan found himself in a confrontation with the Department of Labor. At issue was his practice of employing ski cap knitters who worked at home, treating them as independent contractors rather than paying them a minimum hourly wage. Vaughan, backed by many of the craftswomen, led a two-year defense of "cottage industry."

Monday, March 24

10E2342: Happy Bday Steve

Highway beer toss.

From the beginning 10engines has always been a Steve-free zone but since it is his birthday today what the heck... and the movie Junior Bonner is a real gem/sleeper. Before Peckinpaw directed McQueen and McGraw in The Getaway, he made Junior Bonner. If you don't like westerns atall then this might be a tough one for some but Peckinpah had the chops for this. The rodeo movie is it's own subgenre of westerns (8 Seconds, Cowboy Up, FTW... guilty pleasure the last one). But Junior Bonner has a lot to recommend it, not including a certain actor called Steve McQueen - and a lot of snap pocket action.

The story arc wraps up a little too nicely, but there are great subtexts for the inevitable march of progress (end of the rodeo life for Jnr., construction over farmland, age...) as well as some serious father issues (talking to you Wes Anderson). The barroom is like a second home and there is a huge set-piece dance/brawl that is worth the price of admission.

Tuesday, March 18

10E2341: R Murphy Knives - Made in USA Since 1850 - Part 2

Old logo dug up from the R. Murphy history page.

Continued: last week I had the chance to visit R Murphy Knives - the 3rd oldest knife factory in US (see Part 1) and the tour continues below...

The stamped-out steel blanks are still pliable at this stage so must be hardened. Enter this 1500 degree molten salt bath. They are then quenched in a 400 degree bath and dipped into other solutions... Quench tank FTW! As the hardening, shaping, buffing and sharpening are all done in-house, R. Murphy can turn out upwards of 1,000 units a week - all on premises.

R. Murphy make a point of working with carbon steel for the home chef; it takes an edge better and holds it longer. Julia Child swore by them - I love em too.

The scales (wooden handles) are secured with brass and then sanded to shape - rather than bolting pre-made handles onto the knife and risking a non-smooth ridge. That sander takes the block down in a second - amazing.

I can't remember the punchline but when a guy who sharpens knives for a living tells a joke, you laugh...

That is a 400 grit wheel for those that are interested. Sharpening is done by hand.

Whether the 1980s incarnation of R. Murphy ran a tight ship or not [that owner had a side interest in racing cars - crashed into and beat Paul Newman famously], that letterhead is boss.

Great labels. #staysharp The labels infact printed in Shirley, MA next door. Fan-flippin-tastic. #murphygreen #local

Wall of discontinued styles in the office. The more you dig the more you find. Jump over to their site now for 5% off and free shipping - get yourself a clam and oyster knife and stop by your fishmonger on the way home. #themusicisbetterandthedrinksarefree

Again - must say a huge thank you to Mimi and Mark for taking time out of their day for us, and the staff for taking care of us as well. - James. Photos by Aaron Panone.

10E2340: R Murphy Knives - Made in USA Since 1850 - Part 1

John Murphy started a cutlery business in Boston, Massachusetts in 1850 initially focusing on medical instruments. His brother Robert joined him, changed the focus to knives for the burgeoning shoe industry and eventually moved the business to Ayer, MA around 1906. That building still stands and is still home to the R. Murphy Co. - maker of industrial, commercial and food grade knives - the 3rd oldest, and smallest US knife factory still in existence.

They have also confirmed the companies commitment to creating and finishing the products in-house as well as sourcing materials locally, or in the US as far as possible. Some great stories, for example using 1880s mahogany decking from an old oyster boat then turning that into the handles of oyster knives. #wild They also make those lustworthy blaze handled Island Creek Oyster knives, and have sourced pecan for handles that was salvaged from the flooring of defunct Chrysler plants in Cleveland. They don't yell about it but the stories are all there. Amazing. Almost all the maple handles come from Maine.

The middle row of green handled knives are all for various shellfish; scallops, clams, and oysters of all types. The Murphy green handles are a throwback to their leather cutting tools which had green handles so the wooden handled knives would not get lost among the folds of leather.

An older catalog shows 8 types of oyster knives alone.

Eel spear. For the man who has everything. We have one in fact...

This is a new product, a bartender's knife - created with input from Eastern Standard's Jackson Cannon. It is a jumped up carpet-knife in fact but with a cocobolo handle upgrade. Blunt end is great for fruit work and flat back allows you to scrape the countertop. Genius. $79.

Super heritage-nerds may have heard of Hertler's, the defunct sporting goods retailer from Minnesota (sort of Cabela's before there was a Cabela's, "The arrival of the Herter’s catalog was like Christmas with bullets"*). R. Murphy made their bowie knife, fish fillet and camp knife, and Bull Cook knife; essential for use with Hertler's esoteric Bull Cook and Authentic Historical Recipes and Practices. They still have deadstock - get after it.

Steel Knives are stamped out or cut out with a garnet-water spray (at 55K PSI - can cut through 6" of steel - insane). The skeletons left over from stamping as above are recycled.

Stamped blanks get a hole punched (we'll see why later) then straightened below.

The scale looking apparatus above is for testing hardness of metal, or Rockwells. Don't want to overwhelm you here or get too deep into metallurgy - let's pause and will rejoin for Part 2.

In Part 2 we see hefting (adding handles), 400 grit sharpening wheels, vintage labels and much more.

Monday, March 17

10E2339: Digging Clams - on the Damariscotta River, Maine

David Gilbert has been digging clams on the Damariscotta River since he was a kid, but recent ecosystem shifts on the river have swayed him towards harvesting oysters. Produced by Julie Rawe, Salt Institute for Documentary Studies, ©2013

Julie is a radio producer who is leaping into the world of multimedia storytelling after studying at the Salt Institute for Documentary Studies, in Portland, Maine.Video above a quick slice of life hit from Salt Institute grad Julie Rawe. #find Have been on a huge clam/oyster kick since for ever really, but in last few months especially looking at the lore of shucking to the various tools used. Infact took a day trip this week to visit the RMurphy Knife factory nearby (photos and report to follow). Great people btw and products incredibly reasonable - go treat yourself.

Monday, March 10

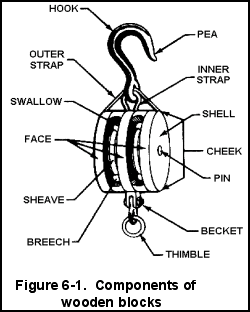

10E2337: Block And Tackle

Archimedes

understood the concept of mechanical advantage, that is the ratio of output and

input forces. Think of a simple bucket on a pulley over a well. That rope and pulley (whether pulling up or down) gives a mechanical

advantage of only 1 as the force applied must be equal to the weight of the

object.

But with a fixed

and movable pulley system (ie a block and tackle arrangement) there are

multiple rope lengths (tackle) at work so the mechanical advantage in

increased. Yes, this is mechanical engineering 101.

Block and tackle being used to lift post into place - via Knobb Hill Joinery

In a block and tackle system the pulleys rotate inside the blocks threaded with tackle, the rope that moves through the pulleys. Traditionally the blocks are made of wood, and are damned attractive if I may say so, in that rustic chic way... Combining several pulleys inside one block increases the leverage, or mechanical advantage but also causes friction on the rope. For most calculations (into which we will not delve here) we ignore the friction created from turning the pulleys, and ignore the weight of the blocks and tackle. Though as the number of sheaves (pulleys) in the block increase, increasing your mechanical advantage, friction does increase, so the direct advantage is not all gained.

Woodblock print of sailors hauling in, from Iron Men and Wooden Ships.

It is generally

accepted that block and tackle arrangements were created for nautical uses (to

tighten rigging, lift sails, move ships) but they are also common on the farm

to move hay up to the top floor of the barn. The gable end of a barn with its

overhang will often feature a block and tackle tied to the top beam.

At our old barn in Weston, VT the dads would sometimes attempt (after some liquid encouragement) to haul themselves up by the block and tackle, putting their foot through a ring on the bottom block and pulling on the rope. Usually the first pull resulted in their raised foot swinging out wide, and they would literally pull themselves off their feet and crash down to earth. Didn’t seem to stop the next man trying. Highly entertaining for the young crowd...

At our old barn in Weston, VT the dads would sometimes attempt (after some liquid encouragement) to haul themselves up by the block and tackle, putting their foot through a ring on the bottom block and pulling on the rope. Usually the first pull resulted in their raised foot swinging out wide, and they would literally pull themselves off their feet and crash down to earth. Didn’t seem to stop the next man trying. Highly entertaining for the young crowd...

This seaside structure is using the block and tackle to move lobster pots. Photo via Katie Hutchison

The objects themselves are things of beauty; rugged, and a visual cue to centuries of work done. They allow one to imagine what could be done with say 3 or 4 times your leveraged power. What would you do?

Nice vintagey examples go for big money; $200 via TDelaney.com.

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.JPG)